To see the beginning and the end in the slightest

Particle size and shape analysis technology can realize the overall morphological evaluation of particulate matter. Morphological imaging technology is an indispensable advanced technology in the characterization of particulate matter. With automatic, rapid and comprehensive particle evaluation system, it can solve the characterization problems of particle shape and size stability in the whole development and manufacturing process, and can provide rapid detection means to identify process deviations for process control and optimization.

The traditional liquid particle counting test instrument can only obtain the basic information of the particle number, but not the particle image, and the test limit can only reach about 1μm. With the development of image processing technology and the improvement of computer processing speed, it is possible to process a large number of particle images in a short time.

W-3000 adopts advanced vision technology to conduct high-resolution imaging of particles in liquid, and can obtain all particle images in test liquid. It not only realizes morphological analysis of particles from 300nm to 1000μm, but also realizes absolute and relative counting of particles.

Product characteristics

With variable magnification telecentric lens, 300nm-1000μm particle imaging can be achieved easily

Using blue pulsed light, can effectively avoid motion shadow

Software automatically identifies adhesive particles on the lens to avoid repeated counting

Three sampling methods: syringe, sample tube, pipette gun

High precision injection pump for accurate fluid metering

Automatic identification of local transparent particles, binary filling

Up to more than 30 particle size parameters, multiple composite filter Settings are available for rapid particle classification

All particles are automatically saved, and specific particles can be exported selectively

Real-time display of particle size distribution and particle count, which can monitor and record the sample change process (optional software)

The software provides statistical tools such as column distribution, box diagram and scatter diagram for horizontal comparison of the same type of parameters and correlation analysis of different types of parameters

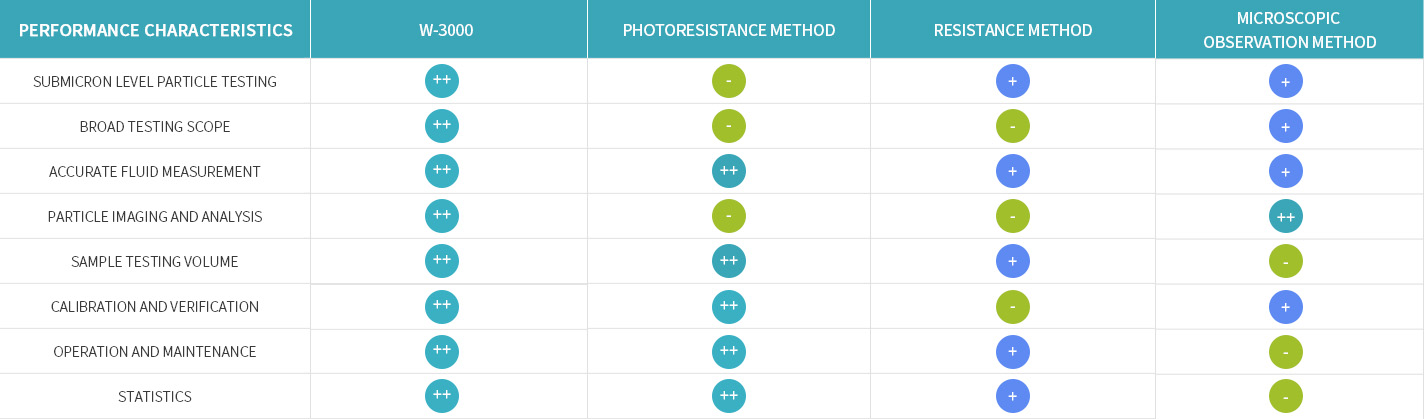

Contrast with traditional methods

Technical parameter

Technology: Microflow imaging

Test range: 0.3-1000μm

Implementation standard: ISO-13322-2:206 GB/T 21649.2-2017

Lens: Auto magnifying telecentric lens

Light Source: 450nm blue pulsed light

Imaging system: 12 million CMOS

Imaging resolution: 4096*3000

Particle size parameters: circumference, area, equivalent area diameter, equivalent circumference diameter, inner diameter, Ferret diameter, Legendre diameter, minimum peripheral circle diameter, mean diameter, skeleton length, etc

Grain shape parameters: aspect ratio, elongation, compactness, straightness, irregularity, roundness, roundness, firmness, concave, convex, bluntness, satellite index, average gray level

SOP Operation process: Supported

Data format: Excel, bitmap, PDF

Liquid volume accuracy: ≤1.0% (1ml syringe and above)

Accuracy of liquid volume: repeatability error ≤0.05% (full stroke, 1ml syringe or above)

Syringe size: 50ul, 100ul, 250ul, 500ul, 1ml, 2.5ml, 5ml optional

Sample recovery: 100% recovery

Size and weight: (L*W*H) 550mm*350mm*350mm, 20kg

Working environment: Temperature: 5℃-40℃; Humidity: below 85% (no condensation)

Typical user